TF | THERMOFORMING

HIGH QUALITY, COST-ATTRACTIVE AND FAST.The perfect technology for durable plastic surfaces with short development times.

Thermoforming (TF) is a traditional, cost-attractive and safe process for medium volume production with short development times.

Our long-standing customers from various industries benefit from our expertise in vacuum thermoforming, especially for interior and exterior panelling.

With over 40 years of experience and more than 20 high-tech thermoforming systems in our global production network, we offer comprehensive expertise and practical experience.

Our long-standing customers from various industries benefit from our expertise in vacuum thermoforming, especially for interior and exterior panelling.

With over 40 years of experience and more than 20 high-tech thermoforming systems in our global production network, we offer comprehensive expertise and practical experience.

- COST-EFFICIENT

PROCESS - HIGH-CLASS

SURFACES - SUSTAINABLE

TECHNOLOGY - SHORT

DEVELOPMENT

Special features of thermoforming

Thermoforming is a proven process that is characterised by high process reliability. It is particularly cost-efficient and ideal for medium quantities.The short development times mean that products can be brought to market quickly.

We utilise state-of-the-art technology, which enables us to guarantee the high surface quality of the components produced.

We also attach great importance to sustainability by using environmentally friendly materials. All thermoformed parts - production waste and components - are 100% recyclable.

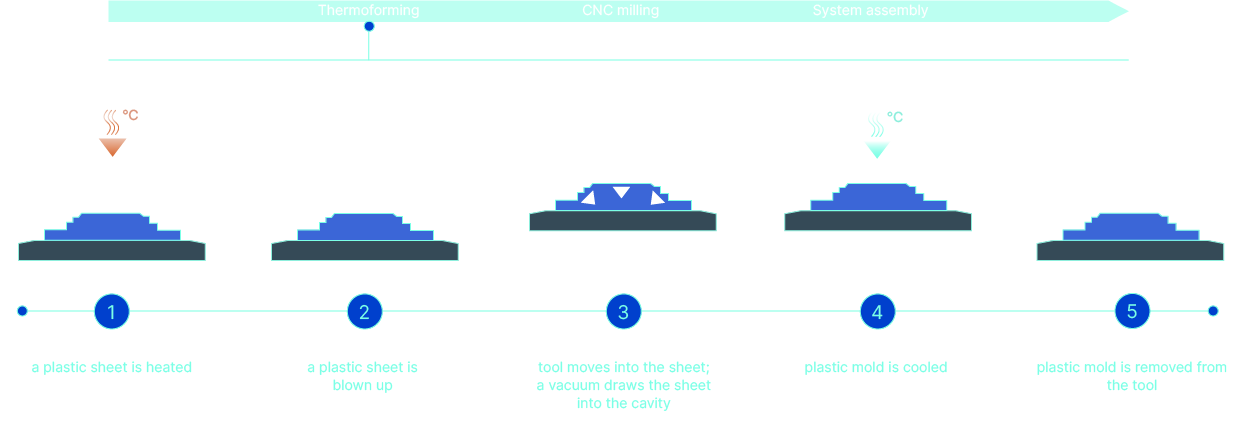

How does the Thermoforming-Process works?

Thermoforming in real life

At the BMW Group, sustainability and resource conservation are moving centre stage. In close cooperation, new materials were sought in order to make existing car boot mats more sustainable. Thermoforming continues to be used in production in order to fulfil customer requirements as usual.Quote Title

The long-term partnership with PARAT Technology is a prime example of joint success in terms of sustainability and innovation.

Purchasing Manager -

BMW Group

PARAT IS THE PERFECT PARTNER

locations in Europe and Asia with TF machines

modern machines for thermoforming

years of experience in thermoforming

Partnership from beginning to end

PARAT Technology is the safe choice for your project - we are at your side every step of the way, from the idea to the market launch.Our modern systems and the concentrated expertise of our employees guarantee first-class results at all times.

FULL-SERVICE PARTNER

Extensive Know-How

Modern

Machines

High supply

Reliability

FAQ about Thermoforming

Thermoforming is often used to produce single-shell cladding parts. The technology is particularly suitable for large components.

-

Which products are manufactured by thermoforming?

Thermoforming is often used to produce single-shell cladding parts. The technology is particularly suitable for large components.

-

Which tools are used for thermoforming plastics?

Temperature-controlled aluminium tools are used for plastics thermoforming. Only one half of the mould is used for forming. This means that the mould costs are lower compared to other technologies.

-

Which plastics can be thermoformed?

Theoretically, all thermoplastics can be thermoformed, for example ABS, PC, PP, PE, PS.