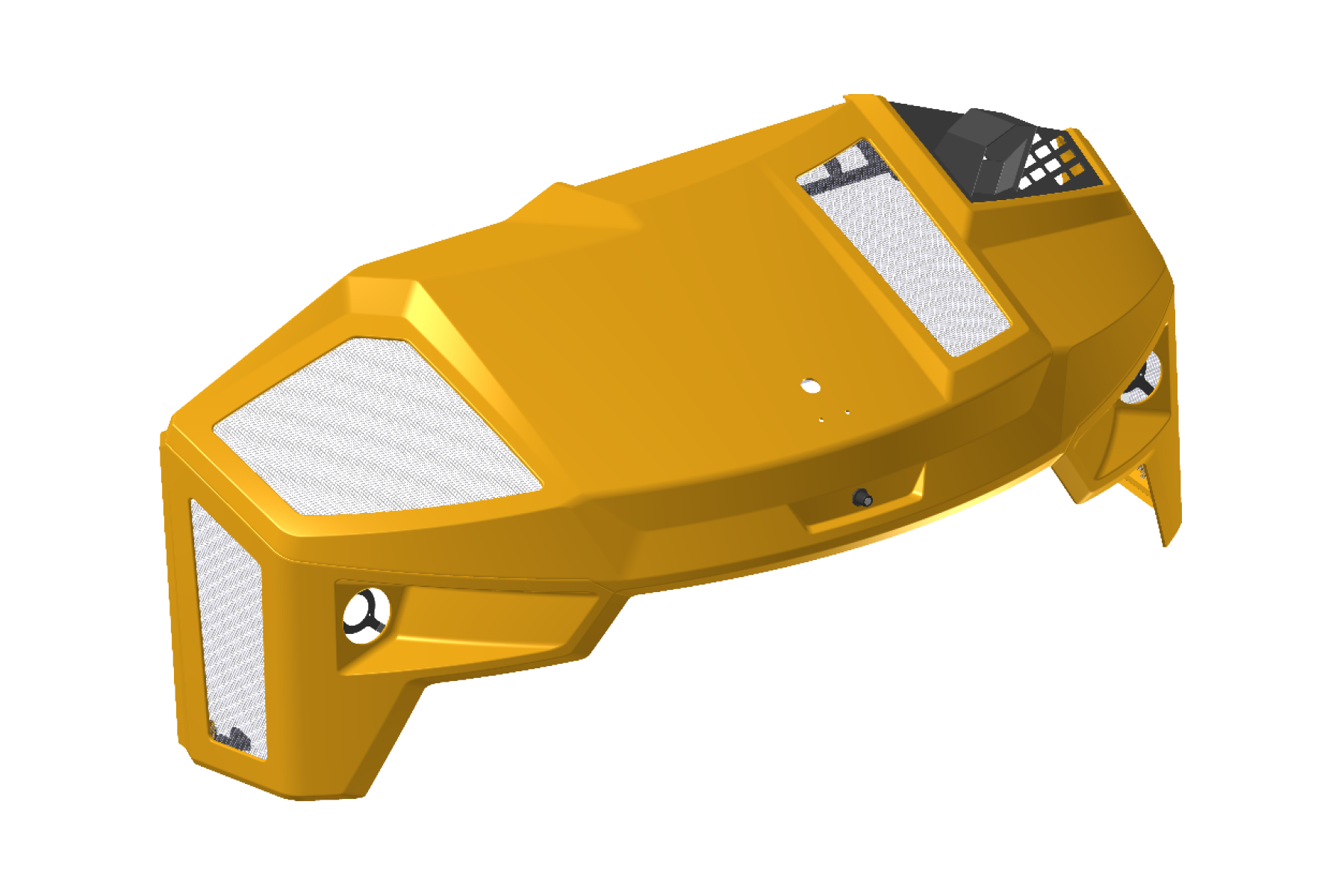

Engine bonnet

SUCCESS STORY WITH LIEBHERR

07.04.2025

| LFI

| Construction machinery

Entering a new era with a new product

PARAT Technology and Liebherr have already realised many projects in their long-standing collaboration.The latest milestone is a completely new compact excavator for which PARAT has developed and manufactured the bonnet, side door and other components.

All components are designed to be stable, robust and at the same time cost-effective to produce. LFI (Long Fibre Injection) technology was chosen as the ideal solution for the bonnet, as the fibre-reinforced plastic components optimally meet the customer's technical requirements. The design freedom of LFI makes it possible to specifically replace metal parts and only use them where they are really necessary.

The project is characterised by a completely revised design with striking and innovative shapes.

Working with PARAT Technology is a pleasure! From the very first idea to the finished product, it‘s always a dialogue at eye level.

Engineering -

Liebherr