RIM | REACTION INJECTION MOLDING

HIGH QUALITY, FLEXIBLE AND FUNCTIONAL.The technology with stunning design and customisation options for plastic trim parts.

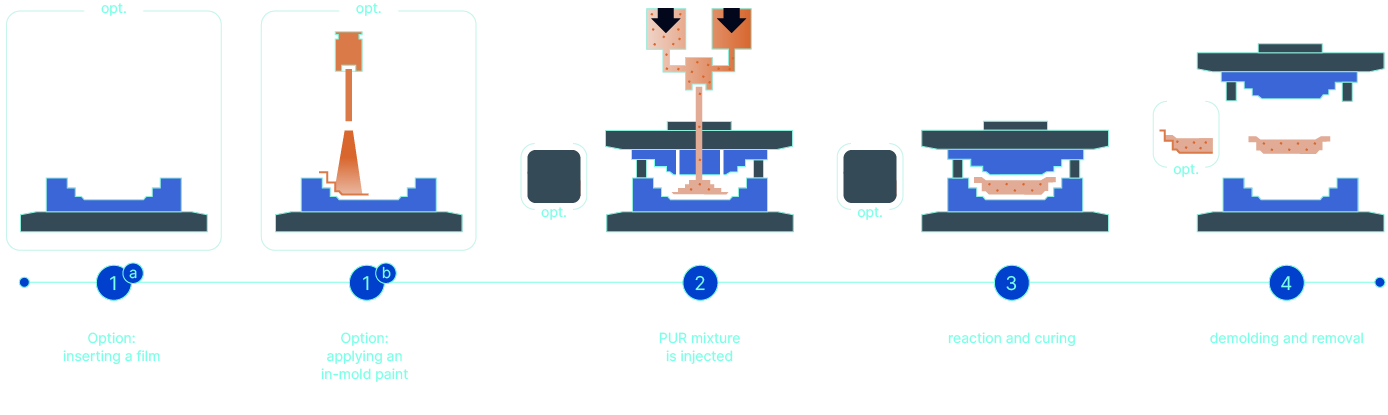

In the versatile RIM technology, polyols and isocyanates are mixed together using the counterflow injection principle. The foaming reaction mixture fills complex mould geometries, even of large components.

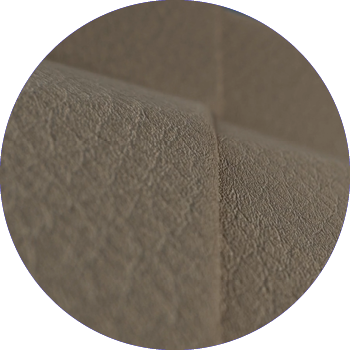

Component densities can be set differently. This creates a high degree of freedom for component functions and surfaces. In this way, high-quality textiles, for example, can be gently back-foamed directly in the mould. The result is economically attractive interior panelling components with textile surfaces and a pleasant feel.

Component densities can be set differently. This creates a high degree of freedom for component functions and surfaces. In this way, high-quality textiles, for example, can be gently back-foamed directly in the mould. The result is economically attractive interior panelling components with textile surfaces and a pleasant feel.

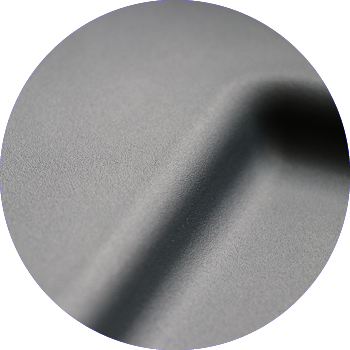

Large-surface exterior cladding components with a modern matt finish and excellent UV stability can also be produced by back-foaming a coating that is applied to the mould in advance.

The low reaction pressures also enable cost-efficient mould construction.

The low reaction pressures also enable cost-efficient mould construction.

- ATTRACTIVE

LIFE-TIME COSTS - LARGE

FREEDOM OF DESIGN - LOW

TOOL COSTS - MATT AND TEXTILE

SURFACES

THE ADVANTAGES OF RIM TECHNOLOGY

RIM (Reaction Injection Moulding) offers attractive lifetime costs for annual quantities of up to 5,000 units thanks to durable materials and efficient production processes.It allows great design freedom for complex and customised shapes and surfaces. Low mould costs make production economically attractive. In addition, matt and textile surfaces can be produced that are both visually appealing and functional.

How does Reaction Injection Moulding work?

Versatile surfaces for interior and exterior applications

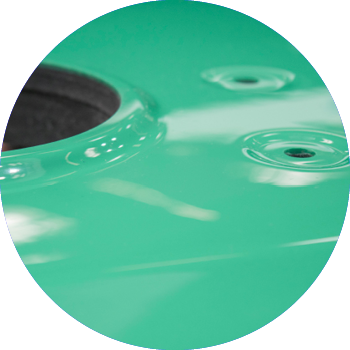

RIM enables a wide range of surface structures and designs for interiors and exteriors, whether smooth, glossy surfaces, textured, matt finishes or other customised solutions.

Class-A

Softtouch

IMC

Coating

RIM IMC for exterior applications

RIM with PVC soft touch for interior applications

PARAT is the perfect partner

locations in Europe and Asia with RIM or (R)RIM machines

modern machines for RIM or (R)RIM

years of experience of RIM

Partnership from beginning to end

PARAT Technology is the safe choice for your project - we are at your side every step of the way, from the idea to the market launch.Our modern systems and the concentrated expertise of our employees guarantee first-class results at all times.

FULL-SERVICE PARTNER

Extensive Know-How

Modern

Machines

High supply

Reliability

Projects with PARAT Technology

We support our partners from the initial idea to the discontinuation of their product. All steps take place in-house, from construction and design to after sales.

-

Can PARAT Technology provide comprehensive support for my project?

We support our partners from the initial idea to the discontinuation of their product. All steps take place in-house, from construction and design to after sales.

-

Do I have a direct contact person?

Our project management team is on hand to answer all your questions and concerns. Order processing can also provide precise information on the status of your product at a later date.

-

Can I come to PARAT Technology with a short-term project?

We can also discuss enquiries at short notice with you. Please get in touch with us using the contact details provided.

-

Will my products arrive on time and reliably?

Our optimised process steps and high machine capacities enable us to achieve high delivery reliability. Coordination and communication between our sites also run smoothly.

-

Does PARAT Technology consider my individual case?

We always approach new enquiries with an openness to technology. This means that we work with our partners to find the perfect solution for planned projects.